You are here:

- CMP Home >

- Web Exhibits >

- Stereoscopic Images >

- Underwood & Underwood

- SUBJECT:

- COMPANY:

- GEOGRAPHIC LOCATION

Stereoscopic Images of Cleveland in 3-D

Underwood and Underwood Publishers

Founded in 1882 in Ottawa, Kansas by two brothers, Elmer and Bert Underwood, Underwood & Underwood was an early producer and distributor of stereoscopic and other photographic images. In 1920, the company sold most of its catalog of stereographs to the Keystone View Company.

- This gallery contains 3 slides. Click on the arrows to advance to the next or previous slide.

- Click on the the photo to see the 3-D rendering.

- To view the total effect of the 3-D versions of the images use anaglyph 3-D Glasses (red/cyan).

-

Piles of iron ore between docks of Lake steamers (right) and railways to mills, Conneaut, Ohio.

We are looking north toward Lake Erie. The steamers over there at our right are on Conneaut Creek. Over 4,000,000 tones of iron ore are brought down here every year by Lake Freighters from the richest iron mines on earth, up at the west end of Lake Superior. here are some of the last 4,000,000 now, forming the long line of stock-piles before us on either hand. Those gigantic arms that reach out over the railway track from their anchorage alongside the creek are part of the huge unloading machinery by whose means the ore in all these piles was taken out of the ships' holds and dumped here. Those long steel girders can reach away across the tracks to stock-piles on the west side. The long string of ore-laden cars is on its way to one of the big blast furnaces to b reduced to pig-iron; most of it will go through the huge converters at Youngstown or Pittsburgh and become transformed into steel— perhaps for a railway track in Africa, a bridge across a Himalayan gorge or a new office building in San Francisco. In order to see the underground mining of iron ore, use Stereograph 7954. For gigantic ore docks at the head of Lake Superior, use 7957. For the process of unloading a steamer in 10-ton handfuls, use 7970. The melting of such ore in a blast furnace can be seen with 5520. No 5523 shows the shaping of steel beams in a rolling mill. From Notes of Travel No. 37, copyright by Underwood & Underwood ("Piles of iron ore between docks and railway, Conneaut, O." is written in six languages, including English, French, German and Russian.) -

Docks, switchyards and 1-ton buckets for lifting iron ore from ships to cars, Cleveland, Ohio.

We are looking north, i.e., towards Lake Erie, over the great ore docks along the "Old River Bed" canal. Here immense quantities of iron from the Lake Superior mines are transferred to trains and shipped to the famous blast furnaces and steel-mills at Youngstown, Pittsburgh and elsewhere in the Ohio river valley, 100 to 150 miles away at the southeast. The partially crushed ore in the cars here at our feet and that soft, earth-like ore in the cars beyond have both come up from near the head of Lake Superior where the biggest and richest iron mines in the whole world are being worked. The hoisting apparatus overhead makes quick work of unloading a freighter, for those suspended buckets hold a ton apiece. They are run out over a vessel, let down into the hold, filled, drawn up, slid across the intervening space and then lowered for dumping into a car, all in a space of time hardly more than it takes to tell about it. If the supply of empty cars is insufficient, the accumulating surplus forms great stock-piles like those straight ahead, at our right. Still more rapid work can be done with immense "clams" that clutch five or ten tons at once; the gigantic steel derricks of such an unloading plant loom up in the distance at our left. We can watch at short rang the operation of such powerful machines by using Stereographs 7963 or 7970. For the mining of this ore, use 7947 and 7954. For its later manufacture into steel, use 5520-5523. From Notes of Travel No. 37, copyright by Underwood & Underwood ("Docks at Cleveland, O., with apparatus for unloading iron ore" is written in six languages, including English, French, German and Russian.) -

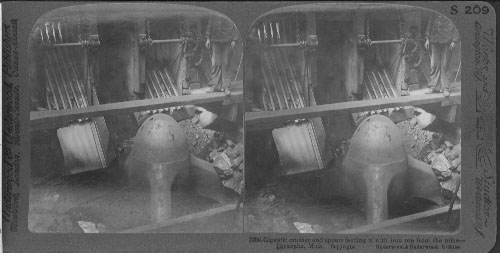

Gigantic Crusher and spouts feeding it with iron ore from the mine - Escanaba, Mich.

We are on the premises of the Oliver Iron Mining Company at Escanaba (norther Michigan). Here the ore-bearing rock taken from Michigan iron mines is crushed by this powerful machinery to get it into shape so it can be handled more easily and with greater economy of space. The economic importance of the process can be inferred from the fact that the company spends $2,000,000 just to install the plant, besides undertaking the expense of running and repairs.

Those spouts let the ore down from huge bins where it is stored when it first comes down from the mine. The crushers in this one establishment can grind yp 4,000 tons a day, ready for shipment east by Lake steamer. A considerable part of the eastern shipments go to Lake Erie ports and are then transferred to trains for the huge blast furnaces and steel mills of the Ohio Valley region (Pittsburgh, Youngstown, etc.). This giant crusher is getting raw material ready for the biggest of all America's enormous manufacturing industries.

For a sight of miners at work 140 feet below the ground, getting out iron ore, use Stereograph 7947. For the unloading of a Lake steamer, use 7970. For the melting of ore in a blast furnace, 5520. For the shaping of a 90 ft. beam of red-hot steel, 5523.